<

Data cooling throughout Northern Ireland

Whilst looking for a water cooled method of dissipating the high output from the blade servers within their Data Centre, NI Water's other performance criteria, included:

- Space inside the data centre was at a premium so the solution had to have a very small footprint

- Resilience was very important as server performance was essential 24/7

- A water leak inside the data centre was not acceptable

- Carbon emissions were to be kept to a minimum, which would result in reduced running costs

- Online monitoring of all aspects of the plant status and room conditions were essential

- The system had to be scalable with increases to both indoor and outdoor capacity possible without major disruption

The Coldlogik data cooling system:

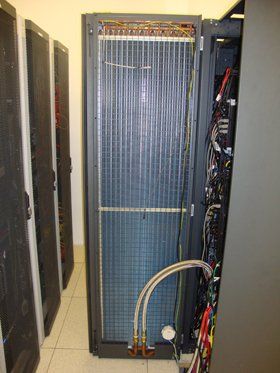

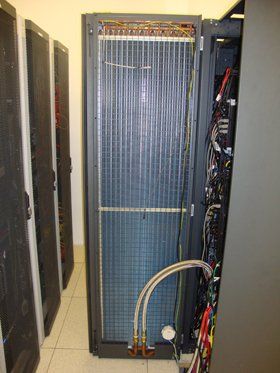

- The solution offered was a Coldlogik system which utilised rear door heat exchangers to extract server heat at source. This is typically about 35°C and allows for high temperature 18°C cooling water to be used. The heat exchangers form the rear door of the rack and take up very little floor space

- The system was designed with run standby pumps, run standby chillers and the drycooler provided additional standby for over 70% of the year

- A unique feature of the system was the use of a venturi arrangement which allowed cold water to be drawn at negative pressure through the heat exchangers and indoor pipework

- If a leak did occur, air leaked into the system rather than water out. This air was collected in the air eliminator and the system status was updated

- The use of high temperature water meant that the chillers would operate more efficiently in temperatures above 16°C and the drycoolers using only fan power provided all of the cooling below 12°C. Running cost savings compared to a Direct Expansion system were projected at over 70%

The installation process:

- A Cylon BMS was used to control and monitor the system and this had a full graphic interface tailored to the client’s requirements and accessible over his intranet by a web browser

- The initial installation consists of 10 server racks, chiller and drycooler. Pipework and flow rates allow for an additional 10 server racks and a second and third chiller to be added. The drycooler has been selected for the projected future load and this over sizing allows reduced running costs with the current load

- Practical completion of the project was ahead of time in August and the system has operated very efficiently through its first winter. The sub-zero temperatures experienced meant that the drycooler was observed operating with only one of ten fans on low speed for long periods

- In this application we have utilized rear door heat exchangers to extract blade server heat at source in a densely populated data centre.

- With flow temperatures of 14-18°C and return of 18-22°C we maintain a room condition of 22-24°C

- These rear doors are effectively vertical chilled beams but capable of higher capacities because we are extracting high temperature heat at 35°C from the blade servers before it reaches the room

- The heat is rejected through drycoolers in temperatures less than 12°C and by chillers and dry coolers between 12 and 16°C

- Above 16°C the chillers handle the load

Our well trained, dedicated engineers are able to offer an excellent level of service and support time and time again.

For more information on data cooling or for an informal chat, call us today on

028 9002 6613